|

|

Toll-Free 1-888-484-9560

Store Locator | NOW HIRING FOR NY STORES

McGard Wheel Locks and Lug Nuts |

Please contact customer service to purchase

|

WHEEL LOCKS: |

|

|

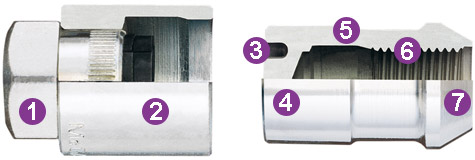

The McGard Wheel Locks protect your valuable wheels and tires from theft. The McGard Wheel Locks are an easy to use one-piece wheel lock, that functions like a regular lug nut, but requires a special key tool for installation and removal. Its design allows for an unlimited number of different computer generated lock and key patterns. This unique wheel lock system is continually being refined and improved upon. McGard Wheel Locks are made in the United States to meet or exceed O.E.M. standards for safety and durability. McGard is an Original Equipment wheel lock supplier to over 30 car lines around the world.

Features:

-

8 different hex key sizes - McGard is the only manufacturer to offer

8 different key hex sizes to match the vehicle’s original equipment lug wrench.

You will appreciate this important feature when you have to change

a flat tire along the roadside.

-

User friendly keys - The steel collar guides the key into the lock pattern.

Simply place the key over the lock and turn until the patterns engage.

The collar holds the key in alignment for easy installation and removal.

-

Computer generated extra narrow groove key patterns -

The computer generated key designs allow for an infinite number of key patterns.

The narrow groove resists the intrusion of lock removal tools into the pattern

-

The best chrome plating in the industry - Includes three layers of nickel and

one layer of microporous chrome. The first layer of nickel is for corrosion resistance;

the second layer of nickel is for luster and the third nickel layer interacts with the

microporous chrome layer to disperse nature’s corrosive action (rust).

-

Through-hardened steel construction - McGard uses use only restricted chemistry steel,

made in the United States. Insures the structural integrity of each and every fully machined

McGard wheel lock. Every lock is through-hardened and tempered, reaching the depth

of hardness needed for its unsurpassed level of security (unlike case hardening which

is only a surface treatment).

-

Precision threads - Core integrity and precision machining provide the highest

strength in the industry. All McGard locks and lug nuts meet or exceed the highest

OEM proof load standards, 135,000 to 160,000 PSI.

-

Precise bearing surfaces - McGard’s standard for concentricity of the bearing surface

to the pitch diameter is 30% more precise than OEM standards. This insures even distribution

of the clamp load and uniform seating of the lock to the wheel.

Installation Video:

|

LUG NUTS: |

|

|

The McGard Lug Nuts are designed to last for life. No chipping, peeling or rusting. Guaranteed to keep on shining for years. The McGard Lug Nuts are manufactured in the USA to meet the highest OEM standards for safety and durability. They’re triple-nickel chrome plated for lasting beauty by using McGard's own in-house plating technology. Every one is backed by a written lifetime guarantee.

Features:

-

Identification - In addition to the thread size and part number, the McGard name

is roll marked into the surface of every nut.

-

Through-Hardened Steel Construction - Every lug nut is through-hardened and tempered,

reaching the depth of hardness needed for its unsurpassed level of safety

(unlike case hardening which is only a surface treatment).

-

Precise Bearing Surfaces - McGard’s standard for concentricity of the bearing surface

to the pitch diameter is 30% more precise than OEM standards. This insures even distribution

of the clamp load and uniform seating of the lug nut to the wheel.

-

Restricted Chemistry Steel - McGard uses only restricted chemistry steel for its

fully machined lug nuts, made in the United States, specifically for McGard.

-

The Best Chrome Plating In the Industry -The process includes three layers of nickel

and one layer of microporous chrome. The first layer of nickel is for corrosion resistance;

the second layer of nickel is for luster and the third nickel layer interacts with the

microporous chrome layer to disperse nature’s corrosive action (rust).

-

Precision threads - Core integrity and precision machining provide the highest strength

in the industry. All McGard locks and lug nuts meet or exceed the highest OEM proof

load standards, 135,000 to 160,000 PSI.

Please contact customer service to purchase

And Get An Instant Coupon Code

And Get An Instant Coupon Code